The

principle of the Eddy Current Separator is fairly

straightforward. Basically, a rotor comprised of magnet

blocks, either standard ferrite ceramic or the more

powerful rare earth magnets depending on application,

are spun at high revolutions (over 3000 rpm) to produce

an ‘eddy current’. This eddy current reacts

with different metals, according to their specific

mass and resistivity, creating a repelling force on

the charged particle. If a metal is light, yet conductive

such as aluminum, it is easily levitated and ejected

from the normal flow of the product stream making

separation possible. Separation of stainless steel

is also possible depending on the grade of material.

Particles from material flows can be sorted down to

a minimum size of 3/32" (2mm) in diameter. There

is no question that Eddy Current Separators have been

a crucial development for the recycling industry.

In a world of

depleting natural resources the race is on to find

faster, cheaper, more efficient ways of reclaiming

and recovering raw materials, as well as improving

the purity and reducing the risk of contamination

during their processing.

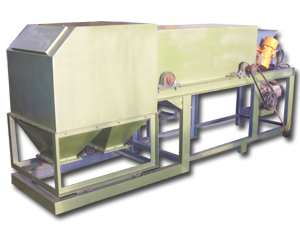

One of the more recent and exciting innovations in

material separation is the non-ferrous Eddy Current

Separator and how it is revolutionizing efforts to

reduce waste and damage to the environment by recovering

valuable non-ferrous metals from municipal and industrial

refuse.

Sorting and separating ferrous metals using magnetized

systems has been standard practice for many years.

Recovering non-ferrous metals, however, was a labor

intensive, costly and a time consuming exercise, only

feasible from bulk materials like incinerated refuse

and fragmentized car scrap. It meant metal mixes,

such as brass, copper, aluminum and steel were relatively

worthless as a mixture and were often landfilled.

It was like pouring money — and vital natural

resources — down the drain.

The Eddy Current Separator is able to separate and

recover aluminum and other non-ferrous metals from

household, industrial and incinerated waste, including

inert plastics and other materials. It is able to

separate metals from scrap, and remove metallic particles

and contaminants from glass and other substances.

In fact, Eddy Current Separators offer a cost effective

method of recovering up to 95% of valuable material

from rubbish and waste, grading precious metal concentrates

for further processing. It also improves the purity

of non-ferrous auto scrap up to 85-95%, maximizing

the speed and efficiency of recovery and increasing

profits.

These systems use the latest and most effective magnetic

circuits to produce strong eddy current forces, which

maximizes efficient separation. Also incorporated

are proven design features, such as quick and easy

machine adjustments, single source dependability,

and energy efficiency.

|